Water restrictions vary by region or water authority.At Daisy, we work hard to ensure our pool covers are the most economically sensible and to make sure people know it’s OK to have a swimming pool because, with a Daisy Pool Cover, you can be environmentally responsibly while enjoying your backyard.

When drilling into paving, all care is taken to avoid damage including chipping of surfaces and cracking of pavers.

Unfortunately due to the existing surface or the way existing paving was laid, the age of the paving and the drilling method, we cannot guarantee that there will be no damage nor cracking of the paving or surrounds during the drilling and installation of the plugs.

No responsibility can be taken for damage occurred during this style of installation.

Recently, the industry has seen the introduction of a so-called “breathable pool cover”. At Daisy Pool Covers, we were intrigued by this new pool cover with holes punched in it and thought we would explain what they do and how they work.

Taking a close look at this new breed of pool cover, they are designed with holes punched though the cover. The covers benefits claim that when you allow your pool to breath, it results in a cleaner, longer lasting pool and a healthier swimming environment. What the team at Daisy Pool Covers discovered was no matter what type of pool cover you purchase, there is absolutely no alternative to looking after your pool’s chemical balance and uncovering your pool water once in a while.

Please click here for more detailed information on breathable pool covers.

Install with the bubble side facing the water so you can see the flat surface.

Yes, you can use any suction, pressure or robotic pool cleaner under your pool cover.

Your pool cover does not hinder the pool cleaner operation

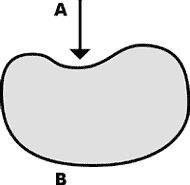

This phenomenon is caused by what we call an inside curve. Adding dressmaking tucks to the curve on some pools, such as kidney shaped ones, will help stop the blanket lifting unevenly, which can be caused by an inside curve. For instance, if you have a kidney-shaped pool, you will find that the material will tend to push from point A towards point B. This is caused by the upturn of the over cut material trying to straighten itself out. It is curved and too large so it creates a force downward. This force is transferred downwards from point A towards point B. If you put some dressmaking tucks into the curve around the A section then this force is contained and the cover will remain stationary.

From the point of view of heating efficiency, no. It will heat effectively even if the pool is not totally covered, however, it will allow dirt and debris into the pool. An edge along a step or an uncovered area will provide a point at which the wind can start to worry the cover and may eventually lift it off the pool.

Provided it is properly fitted, it will not. The effect of the bubbles going down in the water creates more surface area in contact with the water than the flat pool area. Therefore the surface tension is quite high. Further, provided the edges of the cover do not rise above the coping, the effect of any wind is to create a downward pressure which pushes the cover onto the water.

If the cover edge rises above the coping because it has been cut too large, or winter rain has raised the pool water level and hence the cover, then the wind can get under the cover and send it flying into your favourite rose bush (or similar).

Yes. If the air temperature exceeds 35ºC, it is better to remove the cover and place it in a protected, cooler spot. If you have it on a roller with the over-cover on and the temperature reaches this level, it is better to move the cover and roller into the shade.

If you have a Roller System, use the white over-cover supplied every time you recover the cover. If you don’t have a Roller System, the cover must be removed and placed completely in the shade. It must never – not even for a few minutes – be left in the sun when folded. This is because the heat generating effect of the cover is magnified immensely when folded, and it will very quickly self-destruct. The results may not be immediately visible, but they can be very serious.

There can be so much heat created that the air expansion creates sufficient pressure to force the lamination of the two sheets apart, causing the bubbles to join and form lines of larger bubbles. This is not life-threatening to the cover unless repeated consistently, however, the cover can get so hot that it becomes molten and welds itself together – completely ruining it.

Ensure the chlorine level never exceeds 3ppm (3 parts chlorine to 1 million parts water). This level is shown as normal or ideal on your test kit. It is probably best to maintain your chlorine level at 2 to 2.5ppm. This level provides the health department recommended level of sanitation and guarantee your family’s safety. Higher chlorine levels increase the corrosive effects on the cover, and do not increase health standards. In fact, too much chlorine can be potentially damaging to your health.

Run your filter during the hottest part of the day – 10am to 4pm. Normally, when your filter is installed and set up, it is assumed you don’t have a solar pool cover and the filter is set up accordingly by the service person. You’ll be told that if you run your filter during the hottest part of the day your chlorine use will increase. Chlorine in its natural state is a gas.

However you add it to the pool water (liquid, solid or gas), it reverts to its natural state – a gas, which rises through the water and into the atmosphere. When you put a solar pool cover on, much of this evaporation does not occur. Instead, the chlorine continues to circulate through your pool water via your pump and filtration system and continues to sanitise the water.

This means the volume of chlorine in the pool will increase and your water will test higher.With a Daisy solar pool cover, you need to avoid this higher concentration by reducing the input of chlorine into the pool by about 50%. Either put less in (if you physically add chlorine), or turn down the amp-meter if you have a salt water chlorinator.

A further reason to run your filter during the hot part of the day is that when the sun heats the water it only penetrates the thermal layer – about 200 – 250mm or 8 – 10 inches. The sun is only heating the top layer of the pool, which gets hotter and hotter, while the water beneath remains cool. Add high chlorine concentration to this heat, and the effect of UV rays, and it?s the worst possible environment for your swimming pool cover.

By setting up your pump to run during this hot part of the day, you can relieve this heat and get the chlorine evenly distributed through the water again. The pump mixes up the warmer and cooler water to spread the heat and mixes the chlorine throughout the pool and stops it building up under the cover. This allows you to gain the most of the benefits of a Daisy solar pool cover and prolong its life.

The water temperature will rise by 6–8ºC above the average ambient temperature measured over about a week. Most people find they double their swimming season with a Daisy solar pool cover. It is quite normal in mid-summer for the pool to reach 30ºC or more – at which point it will probably too hot, and you will leave the cover off for a period to allow it to cool down.

There will not be as much dirt in the pool if a cover has been used. Dirt will land on the cover and then blow off with the next puff of wind. Without a cover the dirt gets wet and sinks into the pool. Dirt will also tend to end up in one spot, depending on the prevailing wind. You can scoop it off with your hands, or use a broom and dustpan to remove it. You can also turn on your pump and hose the dirt towards your skimmer box.

A Daisy pool cover without a roller is quite a large piece of material, and in practical terms is much easier for two people to handle. You should have one person on either side and concertina the cover on the ground, then fold the sides to the middle and pick it up and store in the shade—not under shade cloth. If only one person is available, they should kneel at the end of the pool, lean out as far as possible, pick up the centre of the cover and draw it towards themselves forming the concertina beneath their knees.

A solar pool cover lives in a very harsh environment. It is constantly attacked by the chlorine in your pool water and UV rays from the sun. The effects of both are magnified by high Australian summer temperatures.

It is the combination of:

Concentration of sanitation chemicals—usually chlorine—in the pool water

Intensity of UV rays

Heat of the pool water.

Daisy’s advanced UltraDomeTM bubble is the key to the outstanding efficiency and long life of our solar pool cover. Exclusive to Daisy, the UltraDomeTM technology completely eliminates weak points in the bubble which can eventually wear and break down. Daisy’s advanced manufacturing techniques use super toughened polyethylene containing the maximum antioxidants, tougheners and UV inhibitors to resist salt, sun and chemical. Together, these factors mean a stronger cover that will last longer.

Daisy pool covers do have a finite lifespan and will eventually require replacement. Remember, your care of the cover will ultimately determine its life.

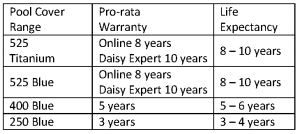

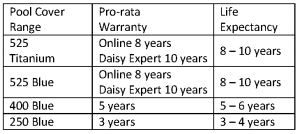

Typical life expectancies:

When you purchase a Daisy pool cover and roller system, you are effectively committing to an ongoing replacement cost, on top of the initial cover and roller system purchase. This cost will amount to between $80 and $120 per year depending how well you look after your pool cover.

This is around $2.00 per week, which is a small price to pay for the many considerable benefits of owning a Daisy solar pool cover. A solar pool cover lives in a very harsh environment. However, you can take actions to prolong the life of your Daisy solar pool blanket.

UltraDomeTM bubble technology is the heart of our Daisy pool cover structure. The UltraDomeTM bubble profile results in a total insulating air layer to the majority of the bubble depth. The air in the bubble and the air trapped between the top layer of the cover and the water effectively form a thick layer of insulation across the entire cover area.

Thermal resistance (R) is a measure of insulation effectiveness. A Daisy 525 micron pool cover achieves a high rating of 0.1m2 K.

For further information see Ultradome Fact Sheet

A Daisy pool cover prevents evaporation – a process which turns water to gas and dissipates into the atmosphere like a kettle boiling dry. The amount of water loss depends on the surface area of your pool, the temperature of the water and air, humidity and wind. A cover protects the water from these main conditions.

A Daisy pool cover allows the sun’s warmth to pass through into the water. Just like a garden hot house. Water is an excellent absorber of the sun’s heat. All water is heated by the sun and is retained in the pool water by the pool cover as it prevents the heat from escaping.

A Daisy pool cover puts the fun back into a backyard pool. Costs are kept to a minimum and it is an environmentally responsible choice.

A Daisy pool cover is a physical barrier between the pool water and atmospheric temperature.

A cover saves the water from evaporation, heat loss, escaping of chemical pool gas as chlorine turns into a gas when dissolved in water.

No, the seating planks of the Under Bench Roller protect the pool cover so no over-cover is needed

Install the pool cover to maximum water line size then test operation of BGB. The pavers over the edge of the pool can catch the sides of the pool cover acting like a brake. This is of no concern for normal above ground rollers as the roller is picking up, or pulling the cover up and out of the pool. With the BGB’s the cover is being pulled along the ground, meaning the edges are being pulled into the corners not out of them.

Simply trimming the pool cover narrower, to the coping opening size will fix the problem

Note: Square pools and pools with non-round paving generally will ‘grab’ the cover more

When drilling into paving, all care is taken to avoid damage including chipping of surfaces and cracking of pavers.

Unfortunately due to the existing surface or the way existing paving was laid, the age of the paving and the drilling method, we cannot guarantee that there will be no damage nor cracking of the paving or surrounds during the drilling and installation of the plugs.

No responsibility can be taken for damage occurred during this style of installation.

The Daisy Power gives you the convenience of an electric roller without taking up too much space beside your pool. This simple and easy to use electric option allows you to roll up your cover in minutes with the press of a button. The Daisy Power can be retrofitted onto most existing Daisy rollers through a kit, allowing you to upgrade your existing roller. The standard Daisy Power comes as a battery-operated electric roller with AC charger, two remotes and control buttons on the cast aluminium housing mounted on the end frame. For a more environmentally friendly option, you can upgrade to a solar panel to re-charge your Daisy Power! This maintains the battery charge using the sun, meaning your roller is always ready to go.

The roller itself can’t normally be blown by the wind, but there can be reasons why it is being moved in windy conditions.

The ropes have been installed too short. This is raising the end of the cover off the pool surface, enabling the wind to get under the pool cover, move it, and pull the roller (by the cords) into the pool. Install the correct length ropes (2 meters as supplied) and leave them that long so there is plenty of rope between roller and the cover lying flat on the pool. Any excess can be wound around the roller tube.

The roller’s over-cover is being stored on the roller while the pool cover is on the pool. The wind can get under the over-cover (like a sail on a yacht) and propel the roller into the pool. Remove the over-cover and store it elsewhere. This won’t happen with the pool cover stored on the roller and the over-cover installed because of the combined weight of the cover and roller.

The cover is too large and protruding above the side of the pool. The cover is then lifted by the wind, still connected to the roller by the cords, and pulls the roller. See Technical Question: Cover Blowing Off The Pool.

If you can afford the cost, a Daisy Roller System makes using you pool cover a great deal more convenient. It will allow and encourage you to use the cover properly, easily and conveniently and gain the most from the benefits available. A Roller System also provides easy storage, and there is no need to move the cover into the shade as every Roller System includes a protective over-cover at no additional cost. This protects your cover while it is on the roller.

Due to the material construction and the need to fold and pack the material for transport, we have found ThermoTech foam pool covers crease slightly resulting in the cover looking like it is too short in the length, simply leave the cover laid out flat on the pool and over the course of the next 3 to 4 weeks you will notice it ‘grow’ back to the normal size.

This is the material flattening back out from the folding for transport.

Pre cut pool cover data is gathered on new pool shells straight off the mold directly after they have been made, so the swimming pool is as true shape as possible.

When pools are installed into the ground, the base of the pool (the foundation and the back-filling) will change slightly with every installation.

Due to the foundation and back-filling of the pool, the top profile of the pool will alter slightly with every swimming pool installation, some more than others.

Therefore the pool cover fit will be marginally different, not due to the cover changing size or shape but due to the top profile of the pool being slightly changed.

This alteration of the top of the pool profile will alter the pool cover fit and upturn, even showing some water in places. There is no issue or problem with the pool installation nor the cover cut.

Note: Pool covers can be ordered with different margins of oversize or undersize. If no size stipulation is given at time of order the standard 20mm oversize will be supplied. A pool cover fit is correct any time from around a 75mm upturn, to a waterline fit, to a 20mm undersize, the pool cover will still do its job regardless of the fit.

Pre cut pool covers are designed for ease of installation on known pool models.

This degradation will only occur when the antioxidants present in the cover material have been used up. In short, the pool cover has worn out. The antioxidants help protect your pool cover from chlorine’s natural sanitisation process of oxidising everything in your pool. Oxidised plastic can be bleached white, become brittle and will break up when you touch it.

If you have kept the recommended chlorine levels in your pool, then, this oxidised condition will mean that you have achieved the expected life span of the cover and it’s time to replace it. If the pool cover has not achieved its expected life, then it almost certainly has been subjected to excessive chlorine levels – either intermittently or consistently.

Never place the pool cover on a pool with extremely high chlorine levels – for example, when super (shock) chlorinating. This will cause a severe immediate depletion of antioxidants from the cover material causing a significant increase in the oxidisation process and may damage the bubble wall. Monitor chlorine levels regularly and maintain them as recommended at all times. A pool cover that is consistently subjected to even slightly higher than recommended chlorine levels will have its useful life reduced due to an acceleration of the normal oxidisation process.

This is a rare occurrence, and if it happens within the first twelve months of use, Daisy Pool Covers will replace the cover. If the cover is replaced, it is important you understand why it happened to prevent it occurring again. As chlorine reacts with other chemicals and organic material in your pool by-products called chloramines are created. One of these is a gas, Nitrogen trichloride. It is responsible for the strong chlorine smell around pools, particularly indoor pools. When Nitrogen trichloride builds up under the pool cover it can create a very high pressure.

If there is a particularly low-pressure weather cell over the pool, the opposing pressures can create a powerful vacuum that forces the air out of the bubbles. Before installing a Daisy solar pool cover, it is a good discipline to shock chlorinate the swimming pool to burn off residual chloramines and then allow chlorine levels to return to normal. Regular super chlorination or oxidation will avoid any future excessive chloramine build-up. Consult your local pool shop for advice.

For the cover to blow off the pool the wind needs to be able to get underneath it, causing it to lift up and blow across the pool. This may be happening for a number of reasons:

The cover has not been cut to shape and you are attempting to keep it in place by using weighted objects. To work most effectively and not blow off the pool, it is essential the cover is cut to shape and installed correctly, please refer to Installation Instructions.

The cover has been cut to shape (allowing an upturn) but the upturn is too large and protruding above the top edge of the pool. Trim the cover carefully until the upturn is the correct 75 – 100mm and does not go above the pool edge (Coping).

The cover has moved on the pool, showing the water on one side and overhanging the pool on the other side. See Technical Question 3: Cover keeps moving to one side following.

There has been enough rain to significantly raise the pool water level resulting in the cover edge sitting above the coping of the pool. Reduce the amount of water in the pool with your waste water facility or remove the cover until the excess water has evaporated.

This is an extremely rare occurrence and would only normally happen due to a fault in the welding process during manufacture. Notify the company you purchased the pool cover from so Daisy can ascertain the age of the cover and effect a replacement.

This normally happens on a kidney-shaped or curved pool with an ‘inside curve’. When the cover is cut allowing an even 75-100mm upturn all around, the upturn on the ‘inside curve’ tends to push the cover away from that side and up over the opposite edge of the pool. Carefully trim the cover flat to the waterline on the ‘inside curve’ side or put some dressmaking tucks in the upturn along the ‘inside curve’ to alleviate the pressure.

The cover is being moved by water return jets angled up directing the water at the cover – or, jets set too high in the pool. If a jet is aimed up at the cover, loosen it and aim down, away from the cover. If the jets are too high, you may be able to add more water to bring the water level above the return jets. If not, you need to contact your local pool shop about a redirection fitting to move the return water jets further under the water level.

If the pool is kidney-shaped, an unusual shape or has a step area, there needs to be a clear “line of sight” from the roller edges down the pool cover before attempting to roll up. Ensure all step areas are folded over giving you this clear “line of sight” before rolling up. The shape of the pool may tend to push the cover one way, so you may need to pull the cover gently while rolling to keep it straight on the roller.

Ensure the roller position is perpendicular with the main body of the pool so the cover can come up evenly onto the roller.

Ensure the cords are pulling the cover evenly off the water and onto the roller. If not, adjust the cords so the cover is being pulled evenly.

Ensure the cover is being rolled onto the roller over the top of the tube, not underneath.

Ensure the roller is right at the end of the pool, or even extending over the water, before trying to roll in the cover. If the roller is back from the end of the pool (over the pool surrounds) it will make it hard to roll in the cover. Some pool shapes require the roller to be over the water by 1 meter or more to make it work correctly in rolling in the cover.

Daisy solar pool covers consist of two layers of material laminated together. The bottom layer has the moulded bubble shape and is heat-laminated during manufacture to a flat top layer.

De-lamination refers to the two layers separating. This is very rare, but can occur in certain cases.

Material de-lamination caused by faulty manufacture would mean the two layers of material separate completely. This is so rare that since commencement of current manufacturing techniques there has not been one recorded instance.

De-lamination caused by overheating. If the pool cover is left on the roller without the white UV over-cover and exposed to full sunlight for even short periods of time – as little as 5 minutes when it’s very hot – overheating can occur. You will see evidence of this by the top of the bubbles becoming convex – or bulging out – rather than being flat.

In severe cases this can cause pockets of de-lamination. These look like big bubbles, eventually showing a pattern running across the width of the cover, approximately every 600mm.

The de-lamination will typically occur in “patches” at the end of the cover farthest from the roller when on the pool, and about 1-2 meters from the cover edge. In severe cases there will be de-lamination lines across the cover parallel to the roller. You will notice that when you wind the cover onto the roller that the de-lamination lines will line up on top of each other. This is because the sun’s rays hit the top of the roller and pass through the first few layers of pool cover.

The pool cover magnifies the sun’s rays as they pass through – generating enough energy to superheat sections of the cover to a similar temperature to that used to laminate the layers during manufacture. The air inside the bubbles gets extremely hot and expands creating enough pressure to “pop” open the top and bottom layers. De-lamination caused by overheating is not covered under warranty. The solar pool cover will continue to work effectively to warm the pool and prevent evaporation – but you will experience some loss of useful life.

When the pool cover eventually perishes, Daisy will cover the loss of lifespan under the warranty terms. De-lamination by overheating is totally preventable. Always ensure that as soon as you stow the pool cover on the roller, the protective UV over-cover is fitted immediately.

It is important to check the dig templates before you use them, to make sure correct orientation and size before you start digging the hole.

We have found the fold marks can crease the black plastic especially if the dig template has been stored for a long time.

It is important to pull the dig template tight to remove any creases as the creases can simulate the dig template being too small.

A fallen bubble has had the flat side of the bubble layer of material fall into the bubble-shaped lower film when in a semi-molten state during manufacture. These fallen bubbles are not uncommon in all types of ‘sealed air’ bubble products – including our pool covers. We accept a tolerance level of two fallen bubbles per square metre as within the manufacturer’s guidelines. A fallen bubble cell, whilst not cosmetically uniform to the rest of the cover, is not a weak spot (in fact as a double layer of film it is stronger), and it will not affect the warranty, life or performance of the pool cover in any way.

Ultraviolet energy from the sun will quickly break down most forms of plastic molecules. To counteract this, Daisy adds the maximum UV inhibitors to its pool cover material to prolong the life of the product. Due to harsh UV radiation and corrosive pool chemicals, all solar pool covers have a finite useful life, and some breakdown will naturally occur as the cover reaches the end of its expected lifespan. However, there is an important step which will help ensure the cover’s maximum expected life is reached. When the cover is not in use, always store it out of partial or direct sunlight. If a roller system is installed, fit the UV protective over-cover as soon as the cover is rolled off the pool.

Providing the bubbles are inflated and the cover is in place, it warms the water and retains heat. It is as simple as that. In fact, short of covering the pool cover, you can’t stop it warming the water, and even then only partially. There is no way possible for the cover not to warm the water. Only the environmental conditions – temperature and degree of sunshine/cloud – will limit the heat and are the only variable factors.

A small perforation in the plastic cover material is not a major problem. The damage is primarily cosmetic and the cover is just as effective and the warranted life span is not compromised. However, some water may seep through and collect on top of the cover. You can purchase self-adhesive patch material that will cover most small holes or tears when applied to the top of the cover. The patch is cosmetic (but is darker than the colour of the cover) and will stop water coming through the hole.

If water from a salt pool is left on top of the pool cover, the water can evaporate leaving salt behind. This salt crust will not harm the cover in any way, however, it is advisable to periodically wash any salt build up off as it can affect the cover’s solar heating performance by inhibiting the passage of solar energy through the cover. It is practically impossible to prevent any water getting on the top surface of the pool cover, however, try to pull the cover onto the pool with a bow motion to reduce the water that does get on top of it.

The base material Daisy uses to make its solar pool covers comes in a roll 200 metres long and 1.27 metres wide. The material width means that a Daisy pool cover is manufactured from a number of ‘panels’ of material welded together. For example, a Daisy cover for a 3.6 metre wide pool will consist of 3 ‘panels’ welded together. Daisy solar pool covers (and those from all other Australian suppliers) have always been manufactured this way – as it is simply not practical to produce the base material in greater widths. The welded seams are at least as strong as the material itself, and do not affect the cover’s performance or life span in any way.

Overheating occurs when the cover is off the pool, folded or rolled up and left exposed to partial or direct sunlight. Over time, heat builds up within the layers of the folded or rolled-up cover, the plastic becomes more malleable, and the air inside the bubble expands. The expanding air stretches the bubbles and they take on a convex profile, rather than flat. This stretching of the bubble material over areas of the pool cover will abnormally shrink it. Such shrinkage is not covered under the warranty. The cover will continue to work effectively to warm the pool and prevent evaporation; however, you will experience some loss of useful life. When the pool cover eventually perishes, Daisy will cover the loss of lifespan under the warranty terms. Please note – leaving a cover under shade cloth or a patio is not protecting the pool cover from the sun, you must store it in complete shade.

When a new pool cover is unrolled ready for installation, you may see that at one end of the pool cover the start of the seam is not welded. This unavoidable ‘gap’ is where the welding machine has been started from. Extra material has been added to the length of the cover. You simply cut off this ‘unwelded’ area when trimming the cover to fit the pool.

When the cover is rolled up and put into a box after manufacture there can be some folding lines or creases in the material. These will eventually disappear as the material has a memory and will always try to lay flat. If you have a roller, you can accelerate the process by leaving the cover rolled up on the roller with the over-cover in place for a few days.

Minor manufacturing distortions in the base material can give it a slightly wrinkly look. This is not a fault, but an unavoidable consequence of the plastic extrusion process.

When Daisy cuts and welds the material to form the finished pool cover, some heat distortion can accentuate this ‘wrinkliness’. The manufacture and welding processes makes this unavoidable and therefore, normal. It does not affect the pool cover’s performance or life span in any way.

The manufacturing of solar pool cover material uses plastic extrusion under heat and pressure in specialised equipment. It is the nature of the process that some subsequent settlement of the material is to be expected. Up to 1% shrinkage can normally occur in the length of a pool cover during the first 2 weeks, with the maximum of the settling occurring in the first few days (a 9.0 metre cover can shrink up to 90 mm). To allow for this, an extra (minimum) 300 mm is added to the length of the cover from the measured size of the pool to enable the installer to cut the cover to shape and allow an upturn of 50mm – 100mm (average 75mm) all around the pool. This is much more than adequate to compensate for the expected 1% maximum shrinkage in length. If a pool cover has shrunk more than 1% in length, or it has shrunk in width (shrinkage in width does not occur naturally), then the only possible explanation is that the cover has experienced very significant overheating when stored off the pool.

A green pool indicates a high concentration of algae. Algae is a pest organism that is always present, to some extent, in your swimming pool. However, it can become resistant to normal levels of chlorine and breed rapidly if the conditions are right. The conditions that promote algae growth are:

low chlorine levels

warm water

food source (phosphates).

The polyethylene plastic material used in the manufacture of Daisy solar pool covers is permeable to a degree. This means it will allow tiny quantities of liquids or gases to go through it. Some water vapour will permeate the material and enter the bubbles. As the temperature outside the bubble drops below ‘dew point’, the water vapour inside condenses, leaving a small quantity of water in the bubble. This condensation is perfectly normal and does not affect the cover’s performance or life span in any way. As soon as the temperature inside the bubble increases again, the water will evaporate.

Water can enter the bubbles is if the material is punctured by something – an object or rough pool surround. Water trapped in the bubbles may go green as the chemicals dissipate from the water. Water entering some torn or punctured bubbles will not affect the effectiveness or durability of the pool cover – see Technical Question – Rips, tears and holes in the cover. Handle the pool cover with care and be wary of sharp objects or pool edges. You may need to move the roller right to the end of the pool or over the water to avoid dragging the cover across rough surfaces or edges. If the pool has bull nosed coping, this effectively reduces the pool width at the top, so the sides of the cover may need to be trimmed a little shorter to accommodate the narrower space and make rolling off easier.

Water restrictions vary by region or water authority.At Daisy, we work hard to ensure our pool covers are the most economically sensible and to make sure people know it’s OK to have a swimming pool because, with a Daisy Pool Cover, you can be environmentally responsibly while enjoying your backyard.

When drilling into paving, all care is taken to avoid damage including chipping of surfaces and cracking of pavers.

Unfortunately due to the existing surface or the way existing paving was laid, the age of the paving and the drilling method, we cannot guarantee that there will be no damage nor cracking of the paving or surrounds during the drilling and installation of the plugs.

No responsibility can be taken for damage occurred during this style of installation.

Recently, the industry has seen the introduction of a so-called “breathable pool cover”. At Daisy Pool Covers, we were intrigued by this new pool cover with holes punched in it and thought we would explain what they do and how they work.

Taking a close look at this new breed of pool cover, they are designed with holes punched though the cover. The covers benefits claim that when you allow your pool to breath, it results in a cleaner, longer lasting pool and a healthier swimming environment. What the team at Daisy Pool Covers discovered was no matter what type of pool cover you purchase, there is absolutely no alternative to looking after your pool’s chemical balance and uncovering your pool water once in a while.

Please click here for more detailed information on breathable pool covers.

Install with the bubble side facing the water so you can see the flat surface.

Yes, you can use any suction, pressure or robotic pool cleaner under your pool cover.

Your pool cover does not hinder the pool cleaner operation

This phenomenon is caused by what we call an inside curve. Adding dressmaking tucks to the curve on some pools, such as kidney shaped ones, will help stop the blanket lifting unevenly, which can be caused by an inside curve. For instance, if you have a kidney-shaped pool, you will find that the material will tend to push from point A towards point B. This is caused by the upturn of the over cut material trying to straighten itself out. It is curved and too large so it creates a force downward. This force is transferred downwards from point A towards point B. If you put some dressmaking tucks into the curve around the A section then this force is contained and the cover will remain stationary.

From the point of view of heating efficiency, no. It will heat effectively even if the pool is not totally covered, however, it will allow dirt and debris into the pool. An edge along a step or an uncovered area will provide a point at which the wind can start to worry the cover and may eventually lift it off the pool.

Provided it is properly fitted, it will not. The effect of the bubbles going down in the water creates more surface area in contact with the water than the flat pool area. Therefore the surface tension is quite high. Further, provided the edges of the cover do not rise above the coping, the effect of any wind is to create a downward pressure which pushes the cover onto the water.

If the cover edge rises above the coping because it has been cut too large, or winter rain has raised the pool water level and hence the cover, then the wind can get under the cover and send it flying into your favourite rose bush (or similar).

Yes. If the air temperature exceeds 35ºC, it is better to remove the cover and place it in a protected, cooler spot. If you have it on a roller with the over-cover on and the temperature reaches this level, it is better to move the cover and roller into the shade.

If you have a Roller System, use the white over-cover supplied every time you recover the cover. If you don’t have a Roller System, the cover must be removed and placed completely in the shade. It must never – not even for a few minutes – be left in the sun when folded. This is because the heat generating effect of the cover is magnified immensely when folded, and it will very quickly self-destruct. The results may not be immediately visible, but they can be very serious.

There can be so much heat created that the air expansion creates sufficient pressure to force the lamination of the two sheets apart, causing the bubbles to join and form lines of larger bubbles. This is not life-threatening to the cover unless repeated consistently, however, the cover can get so hot that it becomes molten and welds itself together – completely ruining it.

Ensure the chlorine level never exceeds 3ppm (3 parts chlorine to 1 million parts water). This level is shown as normal or ideal on your test kit. It is probably best to maintain your chlorine level at 2 to 2.5ppm. This level provides the health department recommended level of sanitation and guarantee your family’s safety. Higher chlorine levels increase the corrosive effects on the cover, and do not increase health standards. In fact, too much chlorine can be potentially damaging to your health.

Run your filter during the hottest part of the day – 10am to 4pm. Normally, when your filter is installed and set up, it is assumed you don’t have a solar pool cover and the filter is set up accordingly by the service person. You’ll be told that if you run your filter during the hottest part of the day your chlorine use will increase. Chlorine in its natural state is a gas.

However you add it to the pool water (liquid, solid or gas), it reverts to its natural state – a gas, which rises through the water and into the atmosphere. When you put a solar pool cover on, much of this evaporation does not occur. Instead, the chlorine continues to circulate through your pool water via your pump and filtration system and continues to sanitise the water.

This means the volume of chlorine in the pool will increase and your water will test higher.With a Daisy solar pool cover, you need to avoid this higher concentration by reducing the input of chlorine into the pool by about 50%. Either put less in (if you physically add chlorine), or turn down the amp-meter if you have a salt water chlorinator.

A further reason to run your filter during the hot part of the day is that when the sun heats the water it only penetrates the thermal layer – about 200 – 250mm or 8 – 10 inches. The sun is only heating the top layer of the pool, which gets hotter and hotter, while the water beneath remains cool. Add high chlorine concentration to this heat, and the effect of UV rays, and it?s the worst possible environment for your swimming pool cover.

By setting up your pump to run during this hot part of the day, you can relieve this heat and get the chlorine evenly distributed through the water again. The pump mixes up the warmer and cooler water to spread the heat and mixes the chlorine throughout the pool and stops it building up under the cover. This allows you to gain the most of the benefits of a Daisy solar pool cover and prolong its life.

The water temperature will rise by 6–8ºC above the average ambient temperature measured over about a week. Most people find they double their swimming season with a Daisy solar pool cover. It is quite normal in mid-summer for the pool to reach 30ºC or more – at which point it will probably too hot, and you will leave the cover off for a period to allow it to cool down.

There will not be as much dirt in the pool if a cover has been used. Dirt will land on the cover and then blow off with the next puff of wind. Without a cover the dirt gets wet and sinks into the pool. Dirt will also tend to end up in one spot, depending on the prevailing wind. You can scoop it off with your hands, or use a broom and dustpan to remove it. You can also turn on your pump and hose the dirt towards your skimmer box.

A Daisy pool cover without a roller is quite a large piece of material, and in practical terms is much easier for two people to handle. You should have one person on either side and concertina the cover on the ground, then fold the sides to the middle and pick it up and store in the shade—not under shade cloth. If only one person is available, they should kneel at the end of the pool, lean out as far as possible, pick up the centre of the cover and draw it towards themselves forming the concertina beneath their knees.

A solar pool cover lives in a very harsh environment. It is constantly attacked by the chlorine in your pool water and UV rays from the sun. The effects of both are magnified by high Australian summer temperatures.

It is the combination of:

Concentration of sanitation chemicals—usually chlorine—in the pool water

Intensity of UV rays

Heat of the pool water.

Daisy’s advanced UltraDomeTM bubble is the key to the outstanding efficiency and long life of our solar pool cover. Exclusive to Daisy, the UltraDomeTM technology completely eliminates weak points in the bubble which can eventually wear and break down. Daisy’s advanced manufacturing techniques use super toughened polyethylene containing the maximum antioxidants, tougheners and UV inhibitors to resist salt, sun and chemical. Together, these factors mean a stronger cover that will last longer.

Daisy pool covers do have a finite lifespan and will eventually require replacement. Remember, your care of the cover will ultimately determine its life.

Typical life expectancies:

When you purchase a Daisy pool cover and roller system, you are effectively committing to an ongoing replacement cost, on top of the initial cover and roller system purchase. This cost will amount to between $80 and $120 per year depending how well you look after your pool cover.

This is around $2.00 per week, which is a small price to pay for the many considerable benefits of owning a Daisy solar pool cover. A solar pool cover lives in a very harsh environment. However, you can take actions to prolong the life of your Daisy solar pool blanket.

UltraDomeTM bubble technology is the heart of our Daisy pool cover structure. The UltraDomeTM bubble profile results in a total insulating air layer to the majority of the bubble depth. The air in the bubble and the air trapped between the top layer of the cover and the water effectively form a thick layer of insulation across the entire cover area.

Thermal resistance (R) is a measure of insulation effectiveness. A Daisy 525 micron pool cover achieves a high rating of 0.1m2 K.

For further information see Ultradome Fact Sheet

A Daisy pool cover prevents evaporation – a process which turns water to gas and dissipates into the atmosphere like a kettle boiling dry. The amount of water loss depends on the surface area of your pool, the temperature of the water and air, humidity and wind. A cover protects the water from these main conditions.

A Daisy pool cover allows the sun’s warmth to pass through into the water. Just like a garden hot house. Water is an excellent absorber of the sun’s heat. All water is heated by the sun and is retained in the pool water by the pool cover as it prevents the heat from escaping.

A Daisy pool cover puts the fun back into a backyard pool. Costs are kept to a minimum and it is an environmentally responsible choice.

A Daisy pool cover is a physical barrier between the pool water and atmospheric temperature.

A cover saves the water from evaporation, heat loss, escaping of chemical pool gas as chlorine turns into a gas when dissolved in water.

No, the seating planks of the Under Bench Roller protect the pool cover so no over-cover is needed

Install the pool cover to maximum water line size then test operation of BGB. The pavers over the edge of the pool can catch the sides of the pool cover acting like a brake. This is of no concern for normal above ground rollers as the roller is picking up, or pulling the cover up and out of the pool. With the BGB’s the cover is being pulled along the ground, meaning the edges are being pulled into the corners not out of them.

Simply trimming the pool cover narrower, to the coping opening size will fix the problem

Note: Square pools and pools with non-round paving generally will ‘grab’ the cover more

When drilling into paving, all care is taken to avoid damage including chipping of surfaces and cracking of pavers.

Unfortunately due to the existing surface or the way existing paving was laid, the age of the paving and the drilling method, we cannot guarantee that there will be no damage nor cracking of the paving or surrounds during the drilling and installation of the plugs.

No responsibility can be taken for damage occurred during this style of installation.

The Daisy Power gives you the convenience of an electric roller without taking up too much space beside your pool. This simple and easy to use electric option allows you to roll up your cover in minutes with the press of a button. The Daisy Power can be retrofitted onto most existing Daisy rollers through a kit, allowing you to upgrade your existing roller. The standard Daisy Power comes as a battery-operated electric roller with AC charger, two remotes and control buttons on the cast aluminium housing mounted on the end frame. For a more environmentally friendly option, you can upgrade to a solar panel to re-charge your Daisy Power! This maintains the battery charge using the sun, meaning your roller is always ready to go.

The roller itself can’t normally be blown by the wind, but there can be reasons why it is being moved in windy conditions.

The ropes have been installed too short. This is raising the end of the cover off the pool surface, enabling the wind to get under the pool cover, move it, and pull the roller (by the cords) into the pool. Install the correct length ropes (2 meters as supplied) and leave them that long so there is plenty of rope between roller and the cover lying flat on the pool. Any excess can be wound around the roller tube.

The roller’s over-cover is being stored on the roller while the pool cover is on the pool. The wind can get under the over-cover (like a sail on a yacht) and propel the roller into the pool. Remove the over-cover and store it elsewhere. This won’t happen with the pool cover stored on the roller and the over-cover installed because of the combined weight of the cover and roller.

The cover is too large and protruding above the side of the pool. The cover is then lifted by the wind, still connected to the roller by the cords, and pulls the roller. See Technical Question: Cover Blowing Off The Pool.

If you can afford the cost, a Daisy Roller System makes using you pool cover a great deal more convenient. It will allow and encourage you to use the cover properly, easily and conveniently and gain the most from the benefits available. A Roller System also provides easy storage, and there is no need to move the cover into the shade as every Roller System includes a protective over-cover at no additional cost. This protects your cover while it is on the roller.

Due to the material construction and the need to fold and pack the material for transport, we have found ThermoTech foam pool covers crease slightly resulting in the cover looking like it is too short in the length, simply leave the cover laid out flat on the pool and over the course of the next 3 to 4 weeks you will notice it ‘grow’ back to the normal size.

This is the material flattening back out from the folding for transport.

Pre cut pool cover data is gathered on new pool shells straight off the mold directly after they have been made, so the swimming pool is as true shape as possible.

When pools are installed into the ground, the base of the pool (the foundation and the back-filling) will change slightly with every installation.

Due to the foundation and back-filling of the pool, the top profile of the pool will alter slightly with every swimming pool installation, some more than others.

Therefore the pool cover fit will be marginally different, not due to the cover changing size or shape but due to the top profile of the pool being slightly changed.

This alteration of the top of the pool profile will alter the pool cover fit and upturn, even showing some water in places. There is no issue or problem with the pool installation nor the cover cut.

Note: Pool covers can be ordered with different margins of oversize or undersize. If no size stipulation is given at time of order the standard 20mm oversize will be supplied. A pool cover fit is correct any time from around a 75mm upturn, to a waterline fit, to a 20mm undersize, the pool cover will still do its job regardless of the fit.

Pre cut pool covers are designed for ease of installation on known pool models.

This degradation will only occur when the antioxidants present in the cover material have been used up. In short, the pool cover has worn out. The antioxidants help protect your pool cover from chlorine’s natural sanitisation process of oxidising everything in your pool. Oxidised plastic can be bleached white, become brittle and will break up when you touch it.

If you have kept the recommended chlorine levels in your pool, then, this oxidised condition will mean that you have achieved the expected life span of the cover and it’s time to replace it. If the pool cover has not achieved its expected life, then it almost certainly has been subjected to excessive chlorine levels – either intermittently or consistently.

Never place the pool cover on a pool with extremely high chlorine levels – for example, when super (shock) chlorinating. This will cause a severe immediate depletion of antioxidants from the cover material causing a significant increase in the oxidisation process and may damage the bubble wall. Monitor chlorine levels regularly and maintain them as recommended at all times. A pool cover that is consistently subjected to even slightly higher than recommended chlorine levels will have its useful life reduced due to an acceleration of the normal oxidisation process.

This is a rare occurrence, and if it happens within the first twelve months of use, Daisy Pool Covers will replace the cover. If the cover is replaced, it is important you understand why it happened to prevent it occurring again. As chlorine reacts with other chemicals and organic material in your pool by-products called chloramines are created. One of these is a gas, Nitrogen trichloride. It is responsible for the strong chlorine smell around pools, particularly indoor pools. When Nitrogen trichloride builds up under the pool cover it can create a very high pressure.

If there is a particularly low-pressure weather cell over the pool, the opposing pressures can create a powerful vacuum that forces the air out of the bubbles. Before installing a Daisy solar pool cover, it is a good discipline to shock chlorinate the swimming pool to burn off residual chloramines and then allow chlorine levels to return to normal. Regular super chlorination or oxidation will avoid any future excessive chloramine build-up. Consult your local pool shop for advice.

For the cover to blow off the pool the wind needs to be able to get underneath it, causing it to lift up and blow across the pool. This may be happening for a number of reasons:

The cover has not been cut to shape and you are attempting to keep it in place by using weighted objects. To work most effectively and not blow off the pool, it is essential the cover is cut to shape and installed correctly, please refer to Installation Instructions.

The cover has been cut to shape (allowing an upturn) but the upturn is too large and protruding above the top edge of the pool. Trim the cover carefully until the upturn is the correct 75 – 100mm and does not go above the pool edge (Coping).

The cover has moved on the pool, showing the water on one side and overhanging the pool on the other side. See Technical Question 3: Cover keeps moving to one side following.

There has been enough rain to significantly raise the pool water level resulting in the cover edge sitting above the coping of the pool. Reduce the amount of water in the pool with your waste water facility or remove the cover until the excess water has evaporated.

This is an extremely rare occurrence and would only normally happen due to a fault in the welding process during manufacture. Notify the company you purchased the pool cover from so Daisy can ascertain the age of the cover and effect a replacement.

This normally happens on a kidney-shaped or curved pool with an ‘inside curve’. When the cover is cut allowing an even 75-100mm upturn all around, the upturn on the ‘inside curve’ tends to push the cover away from that side and up over the opposite edge of the pool. Carefully trim the cover flat to the waterline on the ‘inside curve’ side or put some dressmaking tucks in the upturn along the ‘inside curve’ to alleviate the pressure.

The cover is being moved by water return jets angled up directing the water at the cover – or, jets set too high in the pool. If a jet is aimed up at the cover, loosen it and aim down, away from the cover. If the jets are too high, you may be able to add more water to bring the water level above the return jets. If not, you need to contact your local pool shop about a redirection fitting to move the return water jets further under the water level.

If the pool is kidney-shaped, an unusual shape or has a step area, there needs to be a clear “line of sight” from the roller edges down the pool cover before attempting to roll up. Ensure all step areas are folded over giving you this clear “line of sight” before rolling up. The shape of the pool may tend to push the cover one way, so you may need to pull the cover gently while rolling to keep it straight on the roller.

Ensure the roller position is perpendicular with the main body of the pool so the cover can come up evenly onto the roller.

Ensure the cords are pulling the cover evenly off the water and onto the roller. If not, adjust the cords so the cover is being pulled evenly.

Ensure the cover is being rolled onto the roller over the top of the tube, not underneath.

Ensure the roller is right at the end of the pool, or even extending over the water, before trying to roll in the cover. If the roller is back from the end of the pool (over the pool surrounds) it will make it hard to roll in the cover. Some pool shapes require the roller to be over the water by 1 meter or more to make it work correctly in rolling in the cover.

Daisy solar pool covers consist of two layers of material laminated together. The bottom layer has the moulded bubble shape and is heat-laminated during manufacture to a flat top layer.

De-lamination refers to the two layers separating. This is very rare, but can occur in certain cases.

Material de-lamination caused by faulty manufacture would mean the two layers of material separate completely. This is so rare that since commencement of current manufacturing techniques there has not been one recorded instance.

De-lamination caused by overheating. If the pool cover is left on the roller without the white UV over-cover and exposed to full sunlight for even short periods of time – as little as 5 minutes when it’s very hot – overheating can occur. You will see evidence of this by the top of the bubbles becoming convex – or bulging out – rather than being flat.

In severe cases this can cause pockets of de-lamination. These look like big bubbles, eventually showing a pattern running across the width of the cover, approximately every 600mm.

The de-lamination will typically occur in “patches” at the end of the cover farthest from the roller when on the pool, and about 1-2 meters from the cover edge. In severe cases there will be de-lamination lines across the cover parallel to the roller. You will notice that when you wind the cover onto the roller that the de-lamination lines will line up on top of each other. This is because the sun’s rays hit the top of the roller and pass through the first few layers of pool cover.

The pool cover magnifies the sun’s rays as they pass through – generating enough energy to superheat sections of the cover to a similar temperature to that used to laminate the layers during manufacture. The air inside the bubbles gets extremely hot and expands creating enough pressure to “pop” open the top and bottom layers. De-lamination caused by overheating is not covered under warranty. The solar pool cover will continue to work effectively to warm the pool and prevent evaporation – but you will experience some loss of useful life.

When the pool cover eventually perishes, Daisy will cover the loss of lifespan under the warranty terms. De-lamination by overheating is totally preventable. Always ensure that as soon as you stow the pool cover on the roller, the protective UV over-cover is fitted immediately.

It is important to check the dig templates before you use them, to make sure correct orientation and size before you start digging the hole.

We have found the fold marks can crease the black plastic especially if the dig template has been stored for a long time.

It is important to pull the dig template tight to remove any creases as the creases can simulate the dig template being too small.

A fallen bubble has had the flat side of the bubble layer of material fall into the bubble-shaped lower film when in a semi-molten state during manufacture. These fallen bubbles are not uncommon in all types of ‘sealed air’ bubble products – including our pool covers. We accept a tolerance level of two fallen bubbles per square metre as within the manufacturer’s guidelines. A fallen bubble cell, whilst not cosmetically uniform to the rest of the cover, is not a weak spot (in fact as a double layer of film it is stronger), and it will not affect the warranty, life or performance of the pool cover in any way.

Ultraviolet energy from the sun will quickly break down most forms of plastic molecules. To counteract this, Daisy adds the maximum UV inhibitors to its pool cover material to prolong the life of the product. Due to harsh UV radiation and corrosive pool chemicals, all solar pool covers have a finite useful life, and some breakdown will naturally occur as the cover reaches the end of its expected lifespan. However, there is an important step which will help ensure the cover’s maximum expected life is reached. When the cover is not in use, always store it out of partial or direct sunlight. If a roller system is installed, fit the UV protective over-cover as soon as the cover is rolled off the pool.

Providing the bubbles are inflated and the cover is in place, it warms the water and retains heat. It is as simple as that. In fact, short of covering the pool cover, you can’t stop it warming the water, and even then only partially. There is no way possible for the cover not to warm the water. Only the environmental conditions – temperature and degree of sunshine/cloud – will limit the heat and are the only variable factors.

A small perforation in the plastic cover material is not a major problem. The damage is primarily cosmetic and the cover is just as effective and the warranted life span is not compromised. However, some water may seep through and collect on top of the cover. You can purchase self-adhesive patch material that will cover most small holes or tears when applied to the top of the cover. The patch is cosmetic (but is darker than the colour of the cover) and will stop water coming through the hole.

If water from a salt pool is left on top of the pool cover, the water can evaporate leaving salt behind. This salt crust will not harm the cover in any way, however, it is advisable to periodically wash any salt build up off as it can affect the cover’s solar heating performance by inhibiting the passage of solar energy through the cover. It is practically impossible to prevent any water getting on the top surface of the pool cover, however, try to pull the cover onto the pool with a bow motion to reduce the water that does get on top of it.

The base material Daisy uses to make its solar pool covers comes in a roll 200 metres long and 1.27 metres wide. The material width means that a Daisy pool cover is manufactured from a number of ‘panels’ of material welded together. For example, a Daisy cover for a 3.6 metre wide pool will consist of 3 ‘panels’ welded together. Daisy solar pool covers (and those from all other Australian suppliers) have always been manufactured this way – as it is simply not practical to produce the base material in greater widths. The welded seams are at least as strong as the material itself, and do not affect the cover’s performance or life span in any way.

Overheating occurs when the cover is off the pool, folded or rolled up and left exposed to partial or direct sunlight. Over time, heat builds up within the layers of the folded or rolled-up cover, the plastic becomes more malleable, and the air inside the bubble expands. The expanding air stretches the bubbles and they take on a convex profile, rather than flat. This stretching of the bubble material over areas of the pool cover will abnormally shrink it. Such shrinkage is not covered under the warranty. The cover will continue to work effectively to warm the pool and prevent evaporation; however, you will experience some loss of useful life. When the pool cover eventually perishes, Daisy will cover the loss of lifespan under the warranty terms. Please note – leaving a cover under shade cloth or a patio is not protecting the pool cover from the sun, you must store it in complete shade.

When a new pool cover is unrolled ready for installation, you may see that at one end of the pool cover the start of the seam is not welded. This unavoidable ‘gap’ is where the welding machine has been started from. Extra material has been added to the length of the cover. You simply cut off this ‘unwelded’ area when trimming the cover to fit the pool.

When the cover is rolled up and put into a box after manufacture there can be some folding lines or creases in the material. These will eventually disappear as the material has a memory and will always try to lay flat. If you have a roller, you can accelerate the process by leaving the cover rolled up on the roller with the over-cover in place for a few days.

Minor manufacturing distortions in the base material can give it a slightly wrinkly look. This is not a fault, but an unavoidable consequence of the plastic extrusion process.

When Daisy cuts and welds the material to form the finished pool cover, some heat distortion can accentuate this ‘wrinkliness’. The manufacture and welding processes makes this unavoidable and therefore, normal. It does not affect the pool cover’s performance or life span in any way.

The manufacturing of solar pool cover material uses plastic extrusion under heat and pressure in specialised equipment. It is the nature of the process that some subsequent settlement of the material is to be expected. Up to 1% shrinkage can normally occur in the length of a pool cover during the first 2 weeks, with the maximum of the settling occurring in the first few days (a 9.0 metre cover can shrink up to 90 mm). To allow for this, an extra (minimum) 300 mm is added to the length of the cover from the measured size of the pool to enable the installer to cut the cover to shape and allow an upturn of 50mm – 100mm (average 75mm) all around the pool. This is much more than adequate to compensate for the expected 1% maximum shrinkage in length. If a pool cover has shrunk more than 1% in length, or it has shrunk in width (shrinkage in width does not occur naturally), then the only possible explanation is that the cover has experienced very significant overheating when stored off the pool.

A green pool indicates a high concentration of algae. Algae is a pest organism that is always present, to some extent, in your swimming pool. However, it can become resistant to normal levels of chlorine and breed rapidly if the conditions are right. The conditions that promote algae growth are:

low chlorine levels

warm water

food source (phosphates).

The polyethylene plastic material used in the manufacture of Daisy solar pool covers is permeable to a degree. This means it will allow tiny quantities of liquids or gases to go through it. Some water vapour will permeate the material and enter the bubbles. As the temperature outside the bubble drops below ‘dew point’, the water vapour inside condenses, leaving a small quantity of water in the bubble. This condensation is perfectly normal and does not affect the cover’s performance or life span in any way. As soon as the temperature inside the bubble increases again, the water will evaporate.

Water can enter the bubbles is if the material is punctured by something – an object or rough pool surround. Water trapped in the bubbles may go green as the chemicals dissipate from the water. Water entering some torn or punctured bubbles will not affect the effectiveness or durability of the pool cover – see Technical Question – Rips, tears and holes in the cover. Handle the pool cover with care and be wary of sharp objects or pool edges. You may need to move the roller right to the end of the pool or over the water to avoid dragging the cover across rough surfaces or edges. If the pool has bull nosed coping, this effectively reduces the pool width at the top, so the sides of the cover may need to be trimmed a little shorter to accommodate the narrower space and make rolling off easier.