Pump Box

The Pool Pump Box - specifically designed for enclosing standard Pool Pumps. Its versatile design means that it will fit 99% of pumps on The Australian market. It has two sliding plates on top, which can be re-positioned to cater for just about any layout. It is made of Australian galvanised steel, powder coated and acoustically lined. The Pool Pump Box assembles in less than 5 minutes with a few simple screws. It comes certified by an acoustic engineer with 70% + noise reduction. The Pump Box is 100% Australian made to withstand the harsh Australian environment & comes with a 7-year warranty for peace of mind.

Assembly time from just 15 minutes, no tools or handiwork experience needed.

Crafted from durable 0.9mm thick Galvanised (BlueScope™) steel, our pool pump and filter enclosures weigh between 60 and 100 kg. Finished with dense Dulux Colorbond™ powder coating, they're designed not to rust for over 15 years. All external and internal accessories are either galvanised or made of solid stainless steel.

Featuring a 20mm thick dressed pine timber piece on the rear panel on the Free Standing models for easy affixing of controller units, Chlorinators, and Power Points/GPOs.

25mm ventilation gaps at the front and back ensure proper airflow, protecting your equipment.

Rear ventilation gaps allow for conduits/wirings to pass through, while the lid can be completely removed for servicing larger equipment. The front door is fully removable, with no bars across the middle, allowing for unhindered access into the box.

20mm thick Acoustic Foam (29/400 grade) is affixed internally on every panel, reducing noise by up to 80%.

Designed with child safety features and lockable options, meeting all state and council requirements.

Key Benefits of Our Pool Filter and Pump Enclosures

- Reduce noise by 80%, certified by an independent Acoustic Engineer.

- Assemble in as little as 15 minutes, with no nuts, bolts, or tools needed.

- Offer more internal space for easier access, with no bars across the middle and a fully removable front door.

- Save money on design and equipment costs compared to inferior alternatives.

- Save money on running costs by reducing electricity usage.

- Comply with all state and council requirements for soundproofing and structural integrity.

- Industrially designed for enhanced sturdiness, yet lighter than other models.

- Made of 0.9mm Australian-made galvanised steel with a thick Dulux Colorbond™ powder coat finish.

- Come with clear 3D & Illustrated installation instructions, available in 10 standard colours with custom options available for a small fee.

- Child safety features make it difficult for children to access the box.

- 100% Australian Made.

The Acoustic Box™ comes in 10 Standard Dulux colours as below. All the colours correspond to a colorbond colour.

We can also cater for custom colours upon request with no added lead time (additional charges apply for custom colours)

Our pool pump & filter enclosures feature a unique design that eliminates the need for nuts, bolts, or tools during assembly. Whether you're setting up a single or double unit, assembly is quick and hassle-free. Single units, typically less than 1.7m in width, take just 15-20 minutes on average, while double units, wider than 1.7m, require 45-60 minutes.

The assembly process is straightforward: the panels are joined together at the bottom using four corner brackets and secured at the top with four corner caps. This ensures a sturdy and durable enclosure for your pool equipment.

Your enclosure arrives flat-packed for convenience. For Sydney metro deliveries, our driver hand unloads the package at your destination. For regional and interstate deliveries, the enclosure is securely packed in large cardboard boxes to ensure safe transportation.

For visual guidance, check out our detailed assembly instructions by clicking here.

Delivery

The Acoustic Box distributes nationwide from our Sydney manufacturing facility. Once your order has been received, it will be made and dispatched within 4-5 working days.

With delivery schedule between 2 and 5 working days to most parts of Australia you could be enjoying your Acoustic Box in no time.

Returns

We are more than happy to provide a refund should the goods you purchased be:

- Faulty or unsafe

- Do not match the sample or description

- Do not do what we said it would

- Do not do what you asked for

Our Returns Policy includes the rights you have under the Australian Consumer Law and provides you with additional benefits in addition to those rights, because your satisfaction is important to us.

What If I got the size wrong? If your goods remain boxed and unopened you may return them within 30 days from your original purchase date for a refund.

Please click here for further information on our returns policy.

-

Deliveries

- Deliveries lead times will be advised to customers at the time of order placement and will generally depend on workload at the time. Typical delivery lead times are within 7 business days within the Sydney metro and 14 days to the regions and interstate.

- The Acoustic Box is unable to guarantee an exact delivery time. Delivery will take place between 7 am – 6 pm.

- Our driver/courier will deliver as per the delivery instructions at the time of placing the order. In the event instructions are not specified, the driver will leave the product(s) as close as practically possible to the front door of the property.

- The Acoustic Box Pty Ltd does not take any responsibility for any lost or damaged product(s) after delivery.

- The goods and/or services rendered remain the property of The Acoustic Box Pty Ltd until full payment is received.

-

Interstate / Regional deliveries & Freight Insurance

- Any delivery outside the Sydney metro area is treated as a regional or interstate delivery.

- Interstate and regional deliveries are delivered via third party couriers and subject to freight insurance.

- The Acoustic Box Pty Ltd™ offers a freight insurance service for $12.95 + GST which covers any damage to the product(s) whilst in transit (before receipt of the product)

- Customers that have paid for the freight insurance service at the time of placing the order or before the order is shipped from our warehouse will be entitled to a free replacement of any damaged parts.

- To claim for a replacement, customers are required to email evidence of the damage within 48 hours of receipt.

- In the event freight insurance is not selected, customers can purchase replacement panels plus any applicable freight charges.

-

Warranties, exchanges, refunds & faulty goods

- Any claims for damaged or faulty products must be reported to The Acoustic Box Pty Ltd within 24 hours of delivery, otherwise it will be deemed the product(s) are received in good order and the full amount as per the invoice is payable.

- In the event the product(s) is damaged or faulty due to an error by The Acoustic Box Pty Ltd, we will deliver new product(s) or panel(s) as per the order details. Delivery date for a replacement will be made within 20 business days. Please note, the replacement delivery fee will be at the customers expense UNLESS freight insurance was purchased with the original order

- Any changes to orders must be communicated in writing to The Acoustic Box Pty Ltd before shipment of the product(s) otherwise it is deemed that the order is correct as per the order correspondence.

-

In the event The Acoustic Box Pty Ltd agrees to exchange a product, the following charges / refunds will apply:

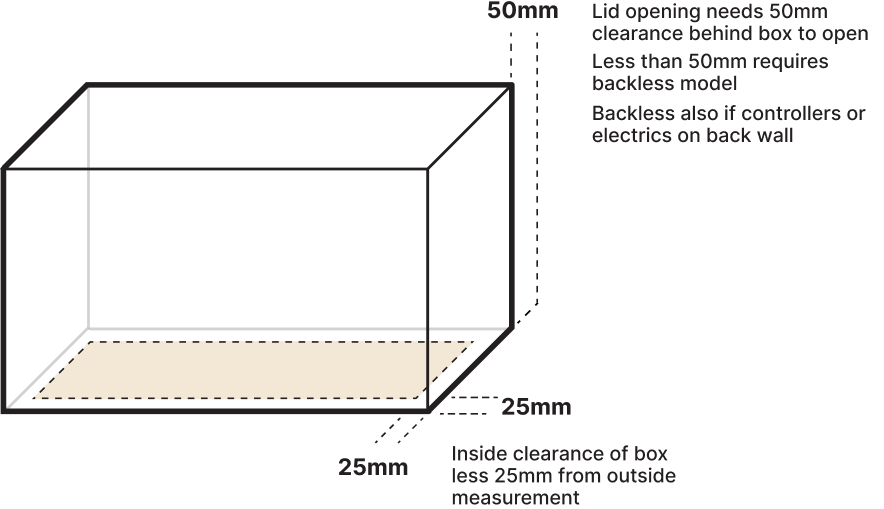

- an exchange from a standard model (with a rear panel) to a backless model (or vice versa): $110+ GST.

- an exchange to a different model: 50% refund of the price of the model to be exchanged

- a delivery or pickup fee (POA) will be charged on all new orders / exchanges.

- The Acoustic Box may refuse exchanges in the event the panels to be excnaged are damaged

- Individual panels may also be ordered. Panel costs vary depending on size and type.

- The Acoustic Box Pty Ltd will only allow exchanges (after delivery) if the goods have not been installed and remain intact in their original wrapping.

- The Acoustic Box does not offer any guarantees with regards to the life of the following items - as this will depend on the location and level of exposure to the elements:

- the powder coating

- the acoustic foam

- the gas struts

- the 'eventual ‘fading of panels.

Notes with regards to the fading of panels (and in particular "lids"):

The effect of sunlight UV rays combining with dirt will break down or oxidise the panels, potentially forming a white chalking effect as well as making the panels fade. “Unwashed areas” will also lead to condensation, which can be absorbed by the dust and dirt that build up in these areas, leading to dissolution of aggressive compounds that may initiate corrosion. The effect is made worse in the vicinity of a salt marine environment, where the build-up includes marine salts and/or other pollutants (e.g. chemicals or industrial residues).

The Acoustic Box suggests regular cleaning with mild soap, sponge and fresh water to remove dirt and grime and to prevent ‘chalking’ which is the white coating on ‘faded panels, and in particular ’ lids. Washing should be done six monthly as a minimum, or three monthly in coastal areas where marine salt spray is prevalent, or in areas with high levels of airborne.

- The Acoustic Box offers a 7-year warranty on all parts of the box. The warranty is either apportioned or pro-rata, as determined at the discretion of The Acoustic Box. Apportionment of warranty means replacement parts will be of similar age (to the initial order). Pro-rata means that a fee may be payable for the replacement part. The fee will be consistent with the warranty period.. This warranty does not cover:

- Intentional or accidental damage to the parts caused by the customer;

- Where the parts have been altered or tampered with;

- Where the parts were installed incorrectly;

- Items outlined in point 4(g)

- where the enclosure is installed within a 200 metre radius to a coastal area

-

Installations

- a standard installation is defined as / includes:

- Installing the footings

- Installing the enclosure, including backless enclosures of any size

- Hole-sawing through the enclosure to let pipes in/out of the enclosure & re-plumbing up to 1 small pipe (if required)

- Attaching timber sleepers to the wall (if required)

- Minor levelling of ground (not more than 20mm gradient / slope – and if required)

- a standard installation does NOT include:

- Major replumbing or moving equipment (EG: relocating a heater or a pump)

- Decommissioning old enclosures and / or disposal

- Major site preparation work such as major leveling of ground etc.

- Once an order (for an installation service) is received the customer needs to email images of the site and description of the work required

- If it is apparent the installation is not a “standard” installation, the customer can elect to have the installation cost refunded or for our installer to attend the site (at no cost) and re-quote for the installation.

- No refund is given for the cost of the enclosure and / or other services & products selected in the event the installation service is cancelled or the new installation quote is not accepted.

- a standard installation is defined as / includes:

Shop by Pool Pump Cover Type

An awesome quality cover

Hi, I thought you might like some feedback on your pool covers! Our 400 micron Daisy is 7 years old and was going pretty strong – I honestly think it had one or maybe 2 years still left in it – that was until is was shredded in a very bad hail storm recently. The hail was larger than golf ball size and many rooves in our area were smashed so we are not surprised it was damaged. It was always kept on the pool unless we were swimming and it’s on a roller that is covered from the sun. Yes it was getting a bit brittle but in general for 7 years we have to say it was an awesome quality cover. Thanks Daisy! Let’s hope the new generation of pool covers are even better. Cheers

Michelle

Committed to Quality

Daisy Pool Covers only offer energy and water efficient products so our

customers can enjoy their pools for longer.